Company Background

Established in 1995, Interquip Electronics is a comprehensive high-tech enterprise in R&D, manufacturing and marketing high precision Quartz Crystal Resonators (including Thermistor Crystals and 32.768KHz Tuning Fork Crystals) and Oscillators (including TCXO, VCXO, LVDS/LVPECL output waveform XO, programmable Oscillators etc.). The frequency components produced can be widely applied in 5G Smart Home, Smart Wear, IoT, IoV, Consumer Electronics, Telemedicine, Automotive Electronics (conforms to AEC-Q200), Communication Industry, Security Applications, Industrial Equipment and other industries.

Interquip owns highly automated production bases of over 40,000㎡ in Shanshan Special Cooperation Zone. Factories are equipped with high-spec dust-free purification workshop with full intelligent monitoring. Interquip is one of the few manufacturers with independent material development and manufacturing capabilities. In order to achieve material independence and continuous quality improvement, the company configures material laboratories and reliability test laboratories to meet the requirements of different markets for materials. The size of crystal resonators and oscillators can be as small as 1.2 x 1.0mm, frequency available from 32.768KHz to 200MHz. With an annual production capacity of more than 1,000,000,000 pcs frequency control components, Interquip has its crystal products exported to Europe, North America, Asia Pacific and other regions. Interquip has sales offices in Chongqing, Suzhou, Shenzhen, Hong Kong, and Taiwan.

Interquip has obtained the system certifications of ISO 9001, IATF 16949, and ISO 14001 etc., and acquired more than 53 invention patents and utility model patents, and the awards of "Shenzhen High-tech Enterprise", "National High-tech Industry", "Best Quality Award", "Guangdong Famous Trademark", "National Advanced Unit of Scientific and Technological Innovation and Quality Management", "China's Top 100 Enterprises of Electronic Components" and so on. Interquip has been granted as "Excellent Supplier" by many customers for years.

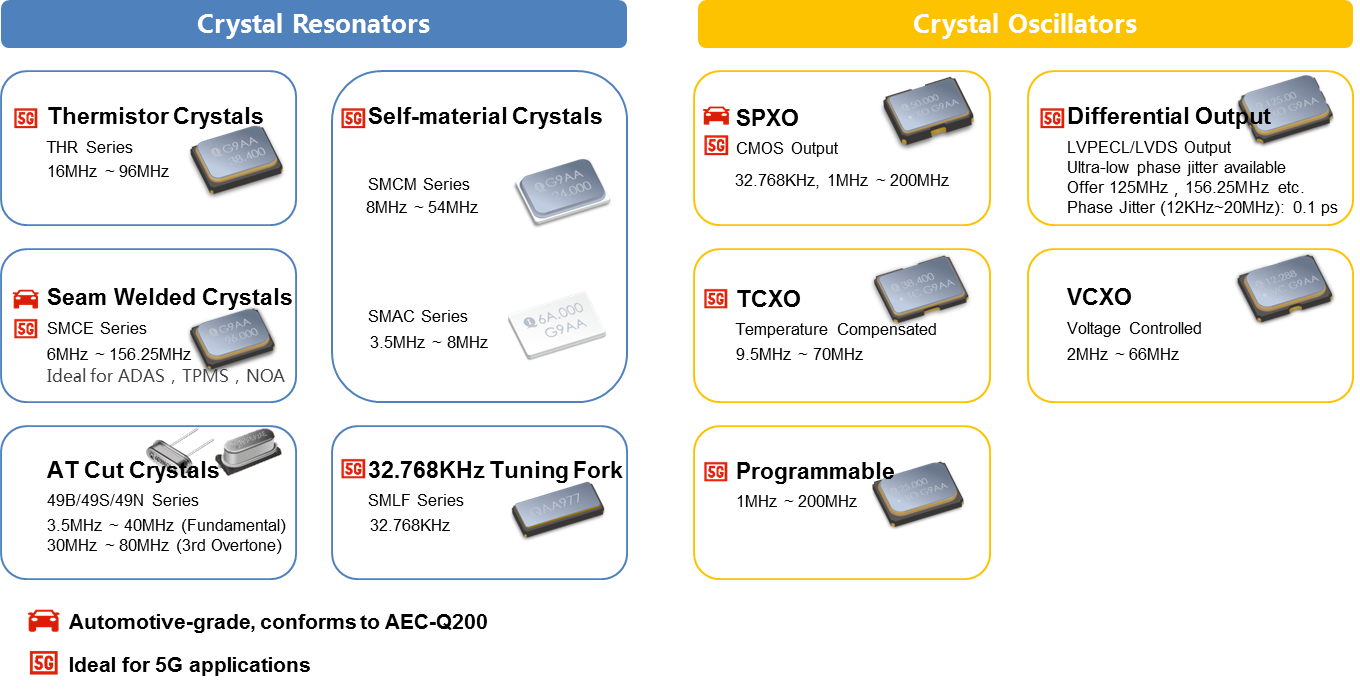

Main Product Line

The products include SMD quartz crystal resonators in the seam welded and all-ceramic enclosures as well as the hybrid (metal cover with ceramic base) enclosures. The size for the SMD crystal resonators ranges from the smallest 1.2 x 1.0mm to the largest 7.0 x 5.0mm package, frequency available from 32.768KHz to 156.25MHz. Quartz crystal resonators are also manufactured with metal enclosures in both standard and high precision.

Other products manufactured by lnterquip Electronics include both lead-free DIP, and SMD clock oscillators, temperature compensated crystal oscillators (TCXO), voltage controlled crystal oscillators (VCXO), and the oven controlled crystal oscillators (OCXO). The size ranges from the smallest 1.6 x 1.2mm to the largest 7.0 x 5.0mm package, frequency available from 32.768KHz to 200MHz with output wave including CMOS, PECL, LVDS, LVPECL and Clipped sine etc..

[00_00_24][20230421-145013].jpg)

Interquip's Strength

Manufacturing processes and materials

Interquip Electronics has developed its own encapsulation processes and packaging materials to counter with the supply chain burden Induced by the dominant commercial suppliers. These encapsulation processes and packaging materials, which were developed over the last two decades including the SMD All Quartz Crystal Resonators (SMAQ series), SMD All Ceramic Crystal Resonators (SMAC series), SMD Hybrid Crystal Resonators (SMCM) and Plastic Encapsulated Crystal Oscillators (166, 178 and 186 Series). These products have advantages over the conventional packages and will benefit our customers with competitive pricing, flexibility in delivery lead-time, while maintaining excellent quality standards.

Equipment development

Interquip Electronics has a long history as a developer of equipment and processes for the quartz crystal components. Our in-house equipment manufacturing facility is capable of producing customized manufacturing and testing equipment that are best suited for our needs for the production of quartz crystal components. This allows us to lower the capital investment cost of our production equipment with added flexibility in production line expansion. The equipment that is built in house including sealing equipment, ion-etching frequency adjustment machines, conventional frequency adjustment equipment, automatic crystal/oscillator test equipment, TC test machines and 3 in 1 robotic for auto equipment testing, laser marking and taping.

Customer Service

The lnterquip Electronics' technical and production staff works hard to understand and fulfill the requirements of every customer and to accommodate special changes in delivery schedules. Our marketing and sales staffs are obligated to respond to all enquiries within a 24 hours frame for standard products. We welcome the comments from our customers as to how we can do better and improve our performance.

[00_00_47][20230421-145244].jpg)

Mission Statement

Interquip Electronics is committed to supporting the expansion and development of the global electronics industry by developing, manufacturing and supplying high quality, competitively priced, quartz crystal based frequency control devices and related technologies. An R&D center is maintained to carry out the objectives of the Technology Roadmap, which involves the development of new products and manufacturing process technologies.

Interquip Electronics is dedicated to being a responsible world citizen, a trusted company that understands both social and environmental factors and requirements and that works hard to fulfill its responsibilities to meet those requirements. As evidence of the company's dedication, its management is committed to meeting the REACH and RoHS II requirements, its factories are all certified ISO14001, ISO9001 and IATF16949.

Interquip Electronics works to fulfill its social responsibilities as a world citizen by promoting the good citizenship, health and happiness of all of its employees and by encouraging them to participate in creative learning experiences so that they will be better able to meet the challenges of life.

[00_01_36][20230421-145835].jpg)